Products

Chattanooga Dual Fuel Burner Products

NU-WAY

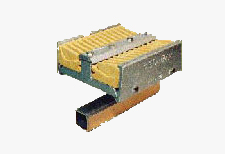

MDF Series (MDFL 1070, 1510, 1880, 2505, 2800, 3300, 4000, 760)

Dual fuel burners are most commonly used if the fuel source is intermittent. By having both gas and oil fuel options available, it ensures the downtime of the boiler is limited. This dual fuel burner is suitable for use with natural gas, LPG, town gas, biogas, and light oil. It can operate effectively with two-stage high/low gas and oil or fully modulating gas and oil operation. All M Series burners are designed and manufactured in accordance with EN676 and EN267.

Features:

- Quick and easy installation

- Reliable and trouble-free operation

- Industry standard components available

- Most components can be easily accessed allowing for easy maintenance.

- Left or right-handed gas trains to reduce the need for a gas booster

- Separate oil pump unit for use when oil is not the primary fuel, designed to reduce oil pump wear when not in use

- Remote fuel changeover.

NDF Series (NDF 100, 125, 150, 180, 35, 50, 60, 85)

Dual fuel burners are most commonly used if the fuel source is intermittent. By having both gas and oil fuel options available, it ensures the downtime of the boiler is limited. All N series burners are custom-built and designed and are designed for Class D (light oil) to Class G (heavy fuel oil) oil and natural gas with 2-stage high/low or fully modulating operations. This range is typically suited for high resistance, hot water, and steam boilers. All N series burners have been designed and manufactured in accordance with EN676 and EN267.

Features:

- Quick and easy installation

- Reliable and trouble-free operation

- Industry standard components available

- Most components can be easily accessed allowing for easy maintenance.

- Left or right-handed gas trains to reduce the need for a gas booster

- Separate oil pump unit for use when oil is not the primary fuel, designed to reduce oil pump wear when not in use

- Remote fuel changeover.

PDF Series (PDF 160, 250, 310, 400, 490, 575, 660)

The PDF dual fuel burner range can be configured for natural gas, LPG or biogas, and Class D or Class G oil. Simultaneous firing and three fuel options are also available. Both oil and dual fuel options are provided with a separate skid mounted oil pump and heater sets to allow for easy installation and maintenance. This burner range is suitable for- larger steam and hot water boilers, thermal fluid heaters, air heaters, breweries, distilleries, paper mills, rotary dryers, etc.

Features:

- Available in monoblock design up to P310 or a duo block design with a floor mounted combustion air fan

- Low NOx Head

- Electronic micro modulation air-fuel ratio control with individual valve servo motors as standard

- Variable Speed Drive (VSD) combustion air fan motor

- Air inlet silencer (< 85dBA)

- Oxygen trim for improved efficiency and reduced emissions

- Separate or integrated water level controls for steam boilers

- Data Transfer Interface for BMS control

ST Series (ST 130, 35, 40, 50, 90)

This burner is suitable for use with both light oil and kerosene with single-stage on/off operation. Available for both conventional and ducted air options and is typically suitable for domestic and commercial hot water boilers, air heaters. Sterling oil and gas burners are commonly used by many boiler manufacturers including Worcester Bosch, Trianco and Grant. All Sterling burners have been designed in accordance with EN676 and EN267.

MO Series (MOL 1175, 1650, 200, 2275, 2540, 2800, 3400, 350, 4100, 540, 795)

This burner is typically suited for commercial hot water boiler and steam boiler systems. Available for use with light oil Class D fuel with single-stage on/off, 2-stage high/low, 3-stage, or fully modulating operation. All M Series burners have been designed in accordance with EN676 and EN267.

GU Series (GU 100, 20, 200, 55)

The GU Series oil burner is designed to use a variety of oils including waste oil as a fuel. The burner features air atomization and an integral oil pre-heater tank to assist the oil atomization to achieve efficient combustion and therefore requires a compressed air supply. All Sterling burners have been designed in accordance with EN676 and EN267.

NO Series (GU 100, 125, 150, 18, 180, 30, 35, 50, 60, 85)

All N series burners are custom-built and designed for easy maintenance. This range is typically suited for high resistance, hot water, and steam boilers. This burner series can fire on Class C to G oil and is designed for 2-stage High/Low or fully modulating operation. NOG burners are accompanied with a burner mounting pumping and heating unit to heat the Class G oil for atomization. The oil temperature is maintained to allow the burner an immediate restart reducing downtime. All N Series burners have been designed in accordance with EN676 and EN267.

PO Series (PO 160, 250, 310, 400, 575, 660)

The PO Series burner can operate on oil (Class D light oil, Class G HFO) and is available in standard outputs from 3.3MW to 18MW. The PO Series burner is commonly used on large industrial steam and hot water boilers. All P series burners are designed and manufactured in accordance with EN267 and EN676.

Features:

- Available in monoblock design up to P310 or a duo block design with a floor mounted combustion air fan

- Low NOx Head

- Electronic micro modulation air-fuel ratio control with individual valve servo motors as standard

- Variable Speed Drive (VSD) combustion air fan motor

- Air inlet silencer (< 85dBA)

- Oxygen trim for improved efficiency and reduced emissions

- Separate or integrated water level controls for steam boilers

- Data Transfer Interface for BMS control

We are proud to offer services and products that are committed to the goals of ENERGY STAR.

We are proud to offer services and products that are committed to the goals of ENERGY STAR.