Services

Nationwide Waste Heat Recovery Services

What Will the Process Look Like?

The starting point for any energy efficiency project is completing an energy audit, a discovery process that utilizes a DOE-created tool known as the Process Heating Assessment and Survey Tool (PHAST). This allows us to go in and take measurements of the application and determine where all of the heat loss areas exist, which gives us insight into how we can best increase the energy efficiency of the equipment at hand. Next our team of experts will create a detailed plan of action to either eliminate those heat loss areas or find creative ways to utilize the heat lost for another application, such as preheating of combustion air, heating water, or creating energy for other uses.

Potential Areas of Heat Loss

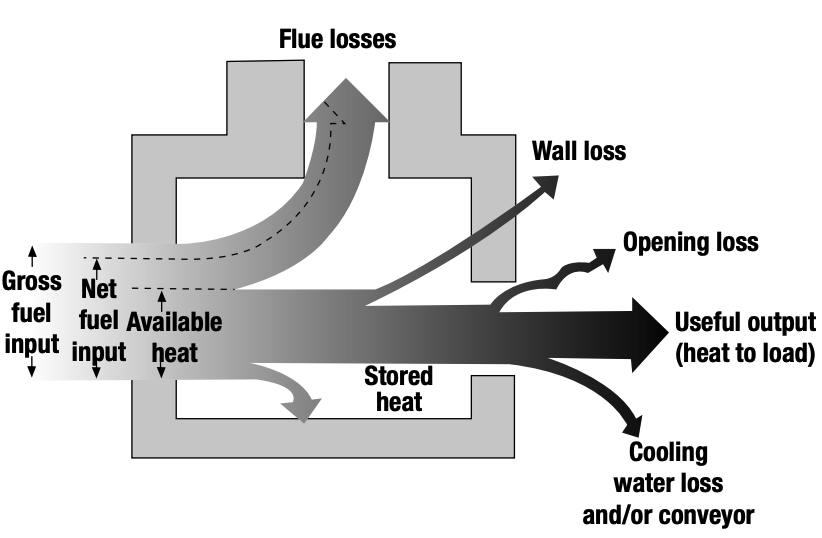

This being said, it is possible to reduce the waste heat losses by taking measures to pinpoint specific areas of loss within an application. Potential areas of loss include:

- Heat storage inside ovens, broilers, dryers, furnaces, or kiln structures

- Losses resulting from the heating process equipment’s outer walls or structure

- Heat that is transported out of the equipment via load conveyors, fixtures, or trays

- Radiation losses from exposed hot parts and other openings

- Heat carried from the process heating equipment by cold air filtration

- Heat carried out by excess air used in burners

Once problem areas are identified, the MSI team will create custom solutions for mitigating these losses of waste heat.

Benefits of Waste Heat Recovery

Our nationwide waste heat recovery services offer many benefits to clients including:

- Increased overall efficiency of processes

- A lower energy component of product costs

- Improved productivity of heat processing equipment used

- Lower emissions of carbon monoxide, nitrogen oxides, and unburned hydrocarbons

We are proud to offer services and products that are committed to the goals of ENERGY STAR.

We are proud to offer services and products that are committed to the goals of ENERGY STAR.