Our team at MSI services and installs many types of PLC’s and building automation systems for a variety of clients. PLC’s such as Allen Bradley, Siemens, as well as Automation Direct, and building automation systems such as Niagara Tridium, Staefa, as well as ASI Controls are just a handful of the systems that MSI designs, services and maintains. This technology and integration serves our customers well, streamlining the work they do for more efficiency and better control when it comes to machines and processes.

That being said, the purpose of these PLC controls is automation, ease of use, and fuller control. When components within the system get outdated, they can throw a wrench in the efficacy of your setup. Our team can help ensure your systems are up to date. Some out of date PLCs cannot be maintained easily, or are impossible to get replacement parts for and can create extended downtime.

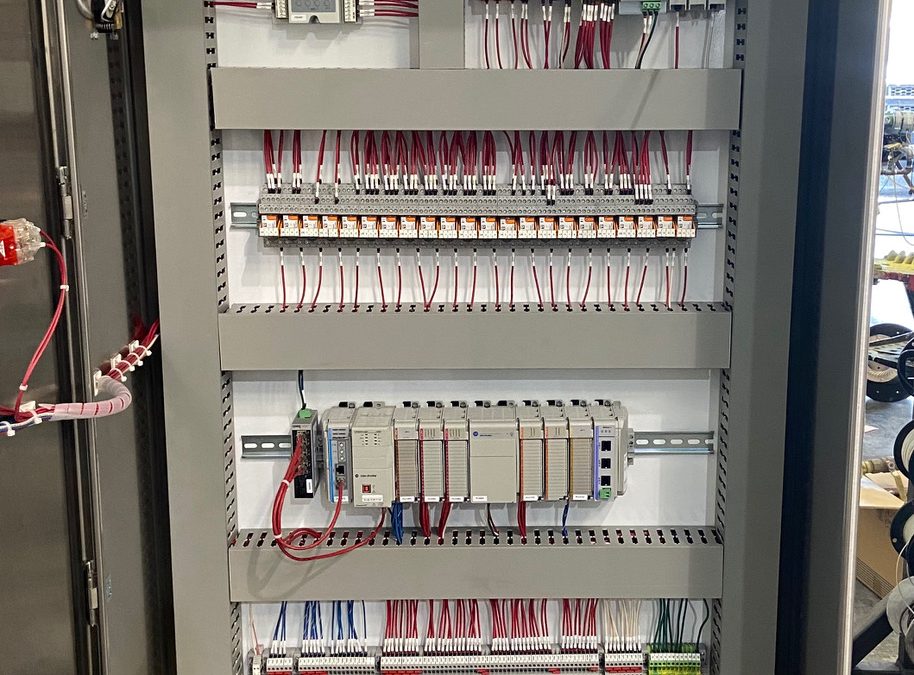

Custom PLC Solutions

Our team works hand in hand with customers to ensure every aspect of their PLCs are programmed exactly how they choose, automating the processes that make the most sense for their businesses. The PLC panels can be programmed to handle everything from all the non-safety burner controls– like temperature control, starting/stopping the system, safety interlocks monitoring, and communicating with the DCS and with our flame safety. We even provide the opportunity for remote monitoring which reduces downtime.

We recently built and programmed a new PLC control panel for a client that controls a Thermal Oxidizer we built for them in house. It is a Siemens PLC, and it communicates with drives and flame safety. This PLC monitors all the safeties and interlocks as well, and will be controlling our TOX unit that will be burning off VOCs for a customer. The customer can specify a certain temperature the TOX unit has to achieve in order to safely burn off the VOCs. Once that is reached, we are able to introduce the VOCs into our TOX unit and burn off the emissions the customer sends us. In this setup, the PLC controls every aspect of this system, other than the flame safety.

Work With Metro

If you are looking into automation controls for your business, or your PLCs need updating, our team can assist with everything from assessing your needs, and creating a custom plan tailored to meet your exact specifications and requirements. Contact us to get started today.

Thermal Oxidizer PLC

Upgraded PLC