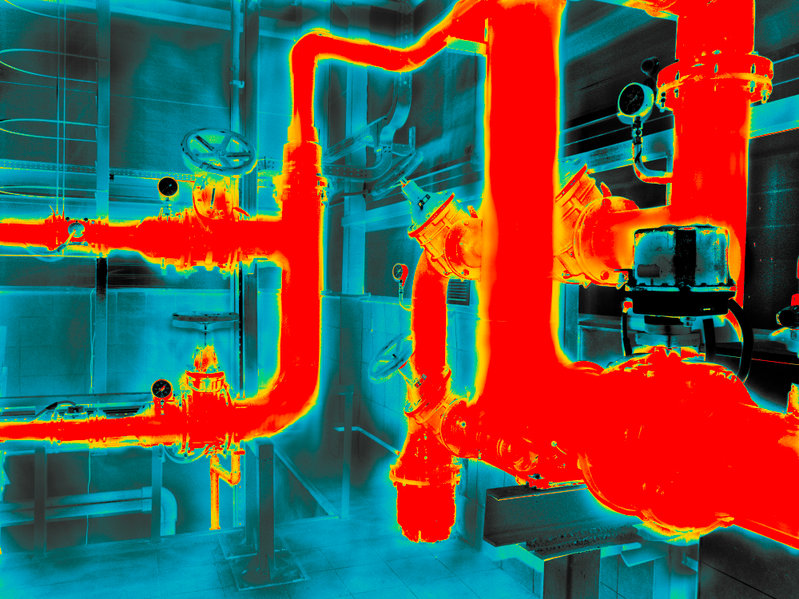

Among their list of global offerings in the way of combustion services, Metro Services, Inc. offers thermal imaging to assist clients with detecting and correcting heat loss. The whole idea is that there can be many things happening that cannot be detected with the human eye, but with the right technology, much can be learned about your facility’s efficiency, and improvements can be made to help boost both productivity as well as your bottom line.

What is Thermal Imaging?

Thermal imaging is a means of improving the visibility of objects through the detection of infrared radiation, then creating images based on that information gathered. Thermal imaging, low-light imaging, and near-infrared illumination are the three most frequently used night vision technologies.

Why Thermal Imaging?

It’s important to ensure that all your equipment is working as it should be, that safety codes are being met, and that any potential problems are caught and addressed early to avoid injury as well as loss of productivity. Thermal imaging, or infrared imaging, works to detect excessive heat within warehouse and factory components. Excessive heat in electrical system components is an indication of potential equipment failure. Overheating components can cause problems that can lead to expensive or even misfortunate failures resulting in costly downtime.

The thermal imaging services our team at MSI offers can help clients save money and reduce downtime within their own operations. Our expert team can accurately locate any abnormalities that threaten employee safety as well as the reliability of your electrical system components by using the latest generation of infrared technology. By finding repairs before failures occur, our customers reap benefits in the areas of productivity, profitability, and workplace safety.

MSI offers thermal imaging inspection servicing for:

- Commercial buildings

- Homes and apartments

- Hotels

- Hospitals

- Manufacturing facilities

- Industrial facilities

- And more

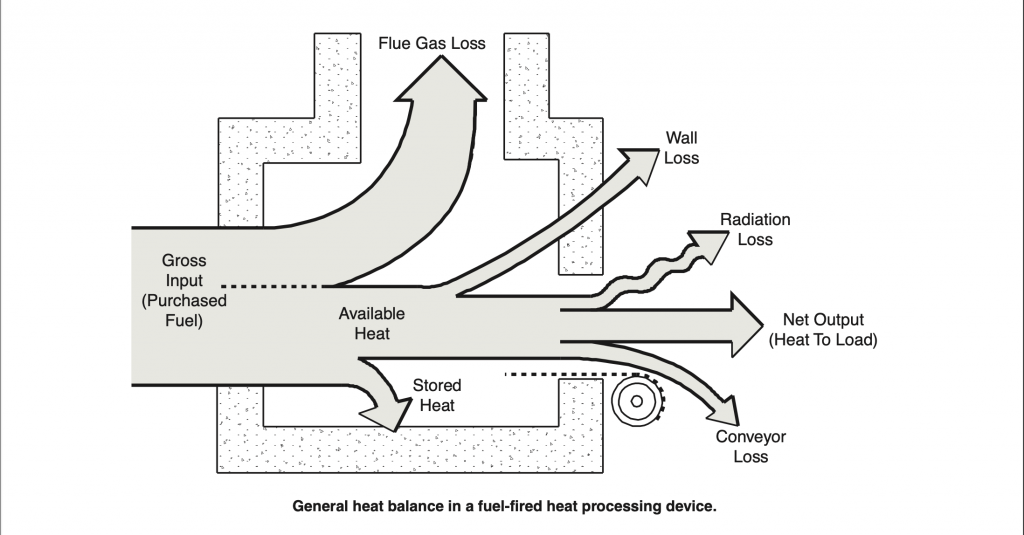

Thermal Imaging in Heat Processing Applications

One area in which thermal imaging is particularly useful is within heat processing applications and specifically ovens. Regular maintenance helps to ensure the efficiency of process heating components and is imperative for avoiding potential heat loss. Thermal imaging, in particular, gives us the ability to identify potential areas of heat loss which result in the need for more fuel to compensate for that loss of heat. There are many areas in which heat loss can occur and result in more fuel needed to perform the same applications. Lack of maintenance, inattention to failure of process components, and overestimating the capabilities of the equipment can all lead to these issues; however, thermal imaging helps us identify and eliminate heat loss for safer and more efficient operations.

Learn more about our combustion services and thermal imaging, and get in touch today with any questions.