Are you certain your process heating systems are up to code? NFPA article 86 mandates that all process heating systems undergo safety audits every single year. This is imperative for the safety of your staff as well as for the efficiency of your systems– but you could also be in a world of trouble if you’re delinquent on your annual safety audits. It’s paramount to check that box in order to keep your business safe and your processes running smoothly, and our team at Metro Services can help.

Some Stipulations of Article 86 of NFPA Compliance

NFPA article 86 mandates are dense, and there is a lot to be aware of. That’s why working with Metro Services provides you and your company a huge advantage as you navigate the ins and outs of these very strict and important requirements. Our team is well-versed in dealing with these stipulations, ensuring that all requirements are met for safety and ultimate performance of your systems.

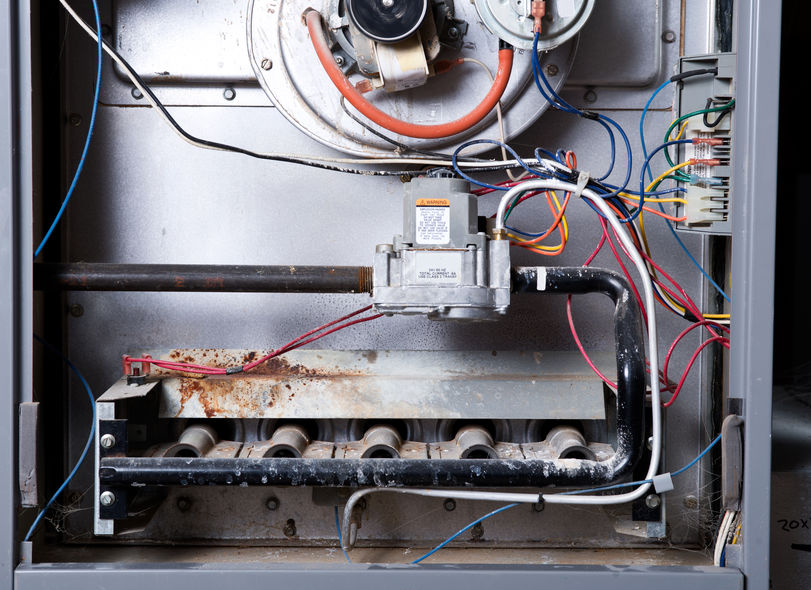

Inspection, Testing, and Maintenance of Burner and Process Heating Systems

- All safety devices must be properly maintained, and this has to be done as per the manufacturer’s instructions.

- The inspection, testing, and proper maintenance procedures must be clearly defined and with the system as per the manufacturer’s guidelines.

- The owner of the process heating equipment is responsible for establishing, scheduling, and enforcing the frequency and extent of the inspections. This does not fall on the manufacturer. The owner of the equipment is tasked with the testing. The bare minimum is annually, and many of our customers choose to have the checks completed semi-annual or even quarterly.

- All safety interlocks must be tested for proper function annually at a minimum. This includes impulse lines connected to safety devices, calibration of continuous vapor concentration high limit controllers, and the set point of temperature, pressure, and flow devices used as safety interlocks. If a relief valve is used it must also be tested at least annually.

- All testing must be documented at least annually. This is extremely important and often overlooked. Our service stores all information digitally for easy access via a customer dedicated web address. This can be shared with you insurance company and safety compliance officer.

- Pressure and explosion relief devices must be inspected visually at least once per year to ensure that they are unobstructed as well as properly labeled. This is also often overlooked or never provided at all.

- Valve seat leakage testing of safety shutoff valves and valve proving systems must be performed in accordance with the instructions provided by the manufacturer.

- Testing frequency shall be annually, at a minimum.

Work With Us

If you need to schedule safety inspections or burner audits, our team would love to help. We are fully committed to helping ensure ALL aspects of NFPA requirements, particularly Article 86, are met, as well as helping your team achieve the safest, most productive work flow possible. Our process heating system safety audits are designed for efficiency as well as ease of implementation. That said, our support services don’t end there. We’re here to provide your team with the best products, education, and resources to help ensure your overall success. Contact us today with any need!