We may or may not be aware of it, but heated enclosures play a large role in many of our daily lives. Furnaces, ovens, and other industrial equipment all fall under the support of the NFPA standards, namely Article 86 guidelines. The codes are constantly being updated, and here at Metro Services, it’s our mission to stay on top of these standards. We help interpret them and pass them along to our clients in a digestible and applicable way, to ensure safety standards are understood and being met.

NFPA Safety Training Courses

NFPA 86 provides guidelines that establish safety measures for operating your facility’s process heating equipment, offering parameters that minimize potential dangers related to fire or explosions that can be extremely harmful and damaging to machines, buildings, or worse yet, people. These codes apply to new installations and modifications of existing equipment, and understanding and enforcing them is paramount to your business.

At Metro Services, we pride ourselves on being able to educate personnel and staff members at various businesses about safety standards, and we also offer combustion training courses. Course material features both lecture style and hands-on learning opportunities with MSI’s test burners and safeguard learning modules. Upon finishing the course, participants will receive a certificate of completion.

NFPA Compliance and Equipment Maintenance

We also offer NFPA compliance surveys and accident investigations, when the need arises. MSI has developed a safety survey that exceeds the NFPA Article 86 guidelines. Our survey also covers the NFPA’s requirement of annual testing, and includes a detailed report of all findings as well as burner adjustments where necessary. In cases where it’s needed, MSI can even tailor the safety survey to meet other requirements, i.e. UL, CSA and other entities.

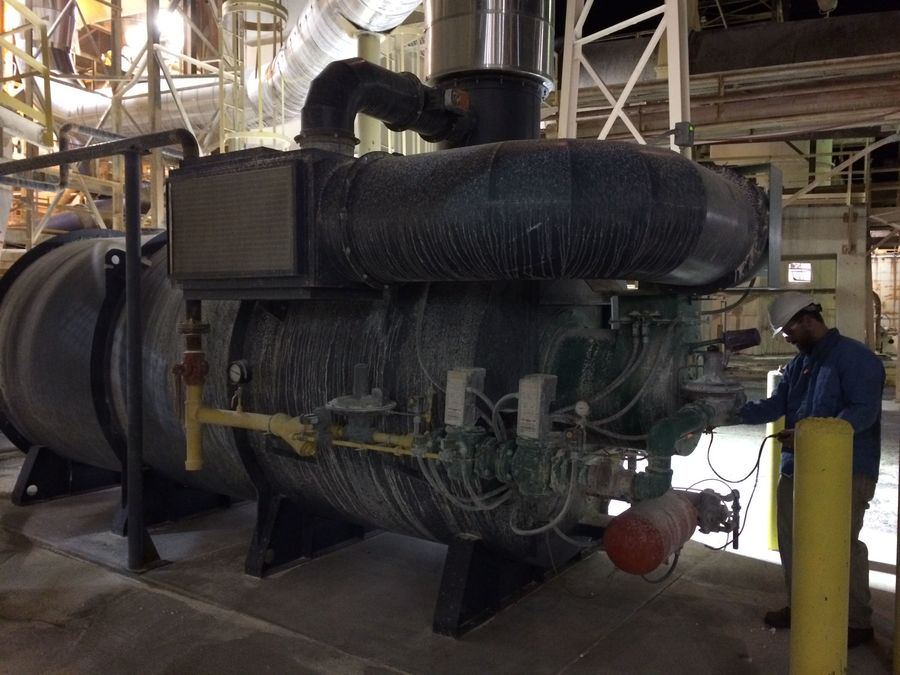

Continuing education and understanding the NFPA guidelines is critical, but so is well-maintained equipment. When you work preventative maintenance into your game plan, you are proactively working toward keeping your business fire and accident-free. MSI, can help here too.

Not only can a well-crafted maintenance schedule help safeguard you and your staff from dangerous accidents, but also it can help increase productivity by eliminating issues before they cause your machines to shut down or interrupt workflow. We recommend planned annual tune-ups that will optimize the performance of your combustion equipment while maximizing operating efficiency. Our preventive maintenance plans impact the reliability, efficiency, and overall performance of your combustion equipment.

Contact us today to learn more, and to schedule your business’ combustion training courses and annual tune-ups.