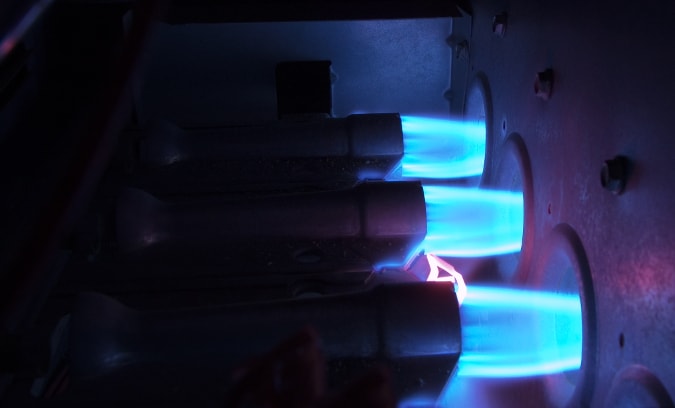

At Metro Services Inc., we’ve been helping to meet the needs of commercial and industrial HVAC customers since 1986. During the early days, we quickly found out that the greater Chattanooga area was in need of companies with knowledge and attention to detail. To fill this need, we flourished and quickly grew from just a few service technicians to a company with more than 45 employees with a world-wide footprint. Over the years, we have expanded our offerings as demand for other areas grew. One of these areas, and the subject of this blog post, was burners. Burners come in many different variations and, as with any device you come to depend on, they need to be maintained or replaced in order to ensure the greatest amount of efficiency is being squeezed out of the system in which they are installed. In today’s post, we are going to go over some of the different types of burners that we offer.

Nu-Way Burners

We make it our mission to be able to supply the best burner for any project, no matter what that project may be. We represent many different styles of burners in order to achieve this goal and work with clients to select the best brand and model for their particular application. We have burners that will fire with almost any fuel, meet the most stringent emissions specifications, and satisfy demands for high or low velocity applications in many different kinds of industrial process heating applications. Below, we have listed a few of the air heating burners that we use on the many projects we are involved in all over the world:

- EC-P – EC-P ranges of packaged burners are able to handle many different applications and are rated for outputs between 120kw to 800kw. This burner is designed to suit all types of low-temperature, gas-fired applications, most typically air heaters, industrial dryers, and box ovens. This burner range is available in configurations that run on natural gas or LP gases with high/low or modulating control.

- ES / ESX – This Energystream industrial in-duct burner is suitable for natural gas or LP gas and is rated for output between 20kW and 12MW with special burners available that are rated for output up to 45MW. The ES / ESX is supplied as a burner head only or as part of an engineered solution, including ductwork if required. This burner can be offered to utilize oxygen with the air stream, as long as it is above 16%, or with a rear airbox designed to accept an external air source. These burners are commonly applied to dryers within the paper and tissue industry, food conveyor ovens, and minerals dryers.

- SD 170 – This Selectos industrial package burner is rated for outputs between 90kW to 190kW and is supplied with an integral fan, fuel train and control box with options available for on/off, high/low, and modulating gas only. This ruggedly designed industrial burner is suitable for use with natural gas, LP gas, or oil, depending on the needs of the industry served. This burner has been used for many years in dryers, furnaces, ovens, and spray booths.

- MDF Series – If you are in an industry where the fuel source is intermittent, dual fan burners are one of the most common ways to bring consistency to the table. By allowing the use of both gas and oil fuel options, the burners help to ensure that the downtime of the boiler is limited, decreasing the amount of money that is lost due to lack of productivity. The MDF series dual fuel burner is suitable for use with natural gas, LP gas, light oil, and biogas and can operate effectively with two-stage high/low gas and oil or fully modulating gas and oil operations. All M Series burners are designed and manufactured in accordance with NFPA 85 and NFPA 86 guidelines. The MDF series features quick and easy installation, left or right-handed gas trains to reduce the need for a gas booster, remote fuel change over, and a separate oil pump unit for use when oil is not the primary fuel.

- PDF Series – The PDF series of dual burners can be configured to run on LP gas, natural gas, biogas and Glass D or Class G oil. This series of burner offers simultaneous firing and both oil and dual fuel options are provided with a separate skid mounted oil pump and heater sets to allow for easy installation and maintenance of the burner. This range of burners is suitable for larger steam and hot water boilers, air heaters, breweries, thermal fluid heaters, rotary dryers, and paper mills.

Thank you for taking the time to read our blog on the different types of burners that we offer. If you would like to learn more about the burners that we offer, or any more of the products and services that have made Metro Services Inc. an industry leader in the process heating industry, please visit our products page or give us a call at 423.870.5558.